In Florida, business owners are liable to up to 14,000 dollars in OSHA violation when their facilities do not comply with cleaning and safety regulations.

Regardless of whether you are in charge of an office building, a manufacturing plant, or a retail space, commercial cleaning compliance requirements will keep your employees and your bottom line safe.

The guide will also assist facility managers and the business owners to develop OSHA approved cleaning procedures that will provide safe and effective working environment.

Introduction to Workplace Safety and Cleanliness in Florida

The relationship between cleanliness and safety in work environment goes well beyond aesthetics. Adequate sanitation in Florida commercial environments forms the basis of regulatory conformity and hazard’s control. Polluted surfaces, poorly handled waste, and ventilation systems provide a thriving ground of accidents and illnesses directly affecting compliance status and operational performance.

The regulation of Florida businesses is a multi-layered system which has been changing over the past few years. The OSHA standards 2025 have brought new stricter regulations concerning the heat safety, lead exposure, and personal protective equipment (PPE) practices.

These federal guidelines operate side by side with Florida-specific regulations, making the compliance environment rather complex and requiring paying careful attention to the cleaning practices.

Not following workplace safety rules can be very costly for businesses. Companies may face fines up to $14,000 for each violation. But the financial impact goes beyond just penalties.

When employees get sick or injured due to poor workplace conditions, several problems arise:

- Workers become less productive

- More workers’ compensation claims are filed

- The company’s reputation suffers

This is why maintaining a clean and safe workplace is about more than just complying with regulations. It’s also a smart business strategy that helps to prevent costly issues before they arise.

What it comes down to, at least in the minds of facility managers and business owners, is the realization that commercial cleaning is not a janitorial service, but rather an important part of operational risk management and compliance.

The most effective Florida companies are the ones that have incorporated cleaning procedures as part of the overall workplace safety plans and have made sanitation a preventive instead of a corrective action.

Florida’s Workplace Safety Requirements

OSHA Standards Applicable to Florida Businesses

Businesses in Florida are required to comply with federal OSHA standards that have undergone considerable updates in 2025. The new heat hazard standard holds employers to institute safeguards when temperatures go beyond the action limits, such as having proper hydration stations, scheduled rest breaks and cooling zones.

In the case of commercial facilities, it means improved maintenance of ventilation, correct cleaning of the HVAC system, and frequent monitoring of air quality.

The new lead exposure limits are especially applicable in construction, manufacturing and renovation works. These standards require increased surface testing and special cleaning procedures of contaminated spaces. Businesses are required to record the lead-safe cleaning practices and have a record of remedial activities.

PPE regulations have changed to focus on appropriate fit testing and records. Cleaning personnel should get education concerning the proper use, choice, and disposal of PPE, particularly when using industrial cleaning chemicals or in case of possible exposure to pathogens.

State-Specific Safety Regulations

Beyond federal rules, Florida has its own requirements that directly impact cleaning operations.

Senate Bill 1886 (Starting July 2025) This new law requires certain employers to create workplace safety committees. These committees must now include cleaning and sanitation procedures as part of their safety responsibilities.

This means that cleaning operations will have more oversight and must meet both federal standards and Florida’s specific workplace safety requirements.

The Department of Business and Professional Regulation in Florida has increased inspection measures of the facilities in high-risk business sectors, especially the cleaning records and sanitation practices. Such inspections are paying more attention to the accuracy of cleaning logs, compliance with chemical storage, and verification of staff training.

Florida has enhanced cleaning requirements over and above the federal requirements, particularly with regard to disinfection procedures and increased sanitization frequencies, in the case of healthcare facilities and food service establishments.

Industry Compliance Mandates

The cleaning-related compliance requirements are different across industries:

The construction sites should have dust containment measures, frequent cleaning of the surfaces to avoid lead build-up, and the construction waste should be properly managed to avoid slip-and-fall injuries.

Healthcare facilities are still under the intense disinfection procedures that were introduced during the COVID-19 pandemic, including the improved terminal cleaning between patient occupancies and the special sanitization of high-touch surfaces.

The food processing and service establishments should comply with the sanitization requirements in Florida which surpasses the federal requirements especially in the cleaning of food contact surfaces and equipment verification.

Cleaning of machinery in manufacturing facilities must be able to avoid not only mechanical failures but also contamination hazards with records that can prove that they were performed in accordance with the manufacturer specifications.

Ensure your facility meets all Florida workplace safety. Click Here

Essential Commercial Cleaning Standards

Daily Cleaning Protocols

Commercial cleaning in Florida should performed using daily systemic procedures depending on the type of facility. In regular office settings, high-touch areas should be disinfected twice a day, such as door handles, elevator buttons, and shared printers and scanners, and restroom fixtures.

Such procedures must employ EPA-registered disinfectants with listed dwell times and procedures.

Stores require increased cleaning frequencies, especially around checkout counters, payment machines and product display areas. Visible cleaning (debris removal) and invisible sanitisation (pathogen reduction) should both be part of the protocol, with clear accountability measures in place.

The daily maintenance of industrial facilities must be specialized to address general cleanliness and process-related contamination.

This involves cleaning production residues, capturing airborne particulates and arranging the regular disposal of waste to prevent the accumulation of flammable or hazardous materials.

Specialized Cleaning Requirements

In addition to daily housekeeping, Florida facilities should follow industry-specific cleaning procedures according to risk managment documents. The terminal cleaning procedures in healthcare settings must be able to address the possibility of pathogen transmission such as UV disinfection, hydrogen peroxide vapor system, or the use of quaternary ammonium compounds according to particular sequencing protocols.

Manufacturing sites are required to have cleaning validation processes in place which records visual cleanliness and the removal of chemical residues. This consists of surface sampling, ATP testing and records that demonstrate effectiveness of cleaning between production runs.

Food service facilities require specific procedures for dealing with food contact surfaces, including approved sanitising procedures and verification. These procedures must comply with the FDA food code and the Florida Department of Health’s guidelines.

Equipment and Supply Specifications

Regulatory cleaning needs the proper equipment and supplies. To avoid redistribution of contaminants, commercial-grade vacuum systems require HEPA filtration that is 99.97 percent efficient at 0.3 microns.

Such systems need written maintenance records and filter changeover calendar.

Microfiber cleaning systems are now considered a basic necessity in any successful surface cleaning, with color-coding systems which ensure there is no cross-contamination between higher risk and lower risk areas. Facilities should have inventories to accommodate appropriate laundry and replacement cycles.

The chemical management systems should consist of correct dilution controls, appropriate labeling as per the requirements of the Globally Harmonized System (GHS), and a written training on the methods of applications.

Safety Data sheets (SDS) should be easily available and there should be verification processes to make sure that the staff understand the hazard communication.

Prevention Strategies Through Proper Sanitation

Identifying High-Risk Areas

A systematic risk assessment of facility areas forms the basis of effective prevention. Entrance zones are critical control points for external contamination entering the building environment. These areas require improved matting systems (to capture up to 80 per cent of particulates within the first 15 feet), regular vacuuming (at least four times a week) and transition cleaning procedures.

Communal places such as break rooms, cafeterias, and conference areas have a higher risk of contamination due to the high concentration of people.

These areas need to be put under a more rigorous disinfection routine especially on common surfaces such as refrigerator doors and handles, microwave buttons and tabletops.

Restroom facilities require a special type of attention and cleaning procedures that should cover both visible soiling and microbial control. This entails well-timed cleaning (cleanest to dirtiest surfaces), correct use of disinfectants with calculated contact time and signed completion checks.

The production facilities need special risk assessment depending on the process, materials, and regulatory needs. Such assessments must be able to determine possible cross-contamination routes, define the suitable cleaning intervals, and introduce a verification protocol that follows the production timetable.

Implementing Preventive Cleaning Schedules

Prevention should be well organised, with a defined frequency and person in charge, as well as checking procedures. Daily maintenance cleaning should target high-touch surfaces and visible soil removal, and this should be documented in digital or paper logs.

Periodic deep cleaning should be performed to include items that cannot be cleaned daily, such as above-floor surfaces, HVAC system parts, and building envelope integrity. These planned interventions should be scheduled according to occupancy trends to cause the least disturbance and have the greatest effect.

Floor maintenance programmes, carpet extraction schedules and building exterior cleaning are specialised preventive measures that ensure long-term deterioration does not occur, creating safety hazards. Such programmes require written procedures, documentation of staff training and quality control checks.

Staff Training and Safety Protocols

Effective prevention requires cleaning staff who are well-trained and familiar with the technicalities of cleaning and the associated safety considerations. Staff should undergo thorough training on the use of chemicals, dilution practices, and application methods, and competency records should be kept.

Preventing cross-contamination will need procedural training in the correct handling of materials, sanitization of equipment between different areas and waste management procedures. Such processes have to be supported by frequent audits and performance feedback.

Well-documented emergency response plans should be in place for cleaning-related accidents (e.g. chemical spills or bio hazard exposure), including designated roles and responsibilities, a notification process and a remediation process. Personnel must be competent in these procedures, as demonstrated through recorded drills and scenario training.

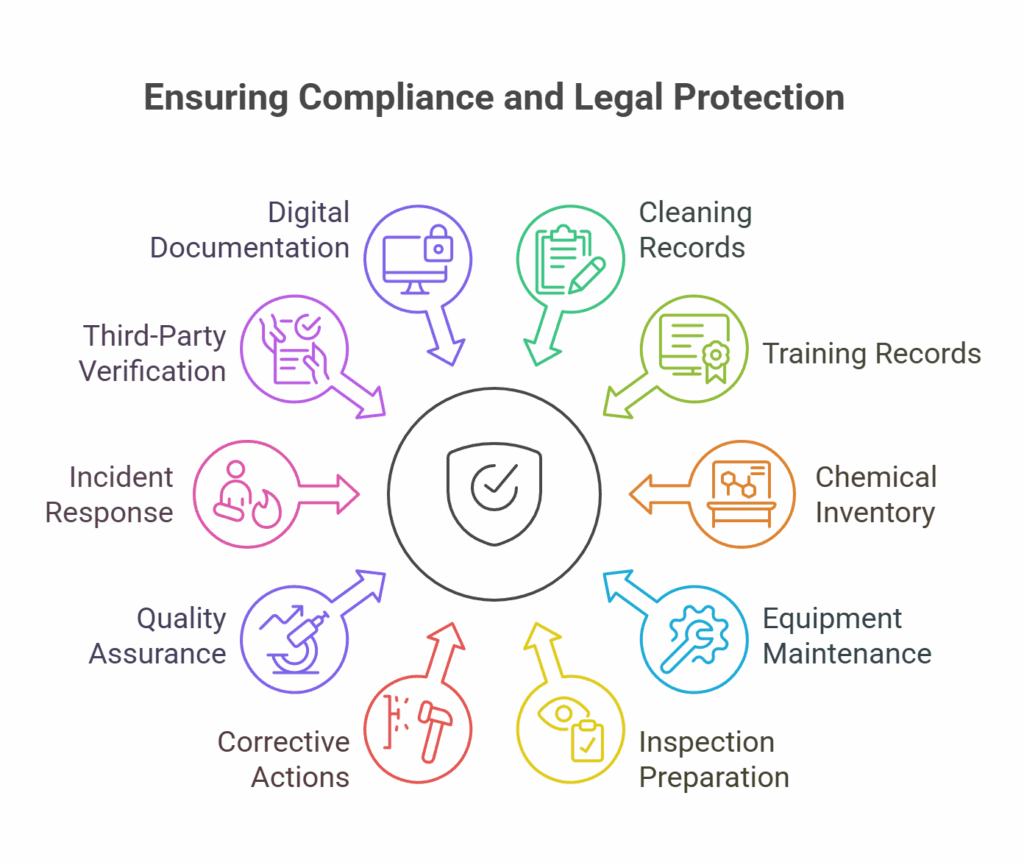

Compliance Documentation and Record-Keeping

Required Safety Documentation

Florida business establishments should have detailed cleaning records that can prove compliance with regulations.

Cleaning logs are the daily records that are considered the primary source of verification of the routine maintenance completion with the indication of the time, personnel in charge, and any issues that were noted and need corrective measures. The logs must be formulated in a way that they comply with the facility-specific protocols and risk assessments.

Training records are an essential part of compliance, as they show the competency of staff in the chemical handling and equipment operation as well as safety procedures. These documents should contain dates of training, summary of content, qualification of instructors as well as proof of understanding by testing or demonstration.

All cleaning compounds utilized in the facility should be documented in chemical inventory, with accurate Safety Data Sheets (SDS), correct storage and usage tracking. This documentation has a compliance and emergency response purpose, and it is used to provide essential information in cases of regulatory inspection or exposure events.

Records on equipment maintenance show appropriate operation of cleaning systems such as replacement of vacuum filters, maintenance of auto-scrubbers and adjustment of chemical dispensing systems. These documents confirm that cleaning equipment is functioning within the specifications of the manufacturer, which guarantees efficient removal of contaminants.

Inspection Preparation and Maintenance Logs

Effective regulatory inspections entail advance documentation plans. The pre-inspection checklists must be able to highlight the key aspects of compliance, such as integrity of chemical storage, appropriateness of labeling of various solutions, the availability of personal protective equipment, and the cleaning logs.

Documentation of corrective actions shows that the management is responsive where shortcomings are noted. These documents ought to contain the type of problem, solutions applied, confirmation that the solutions worked, and preventive steps to stop the same.

Quality assurance programs objectively document cleaning effectiveness through facility-appropriate testing methods such as ATP testing for biological residue, particle counting for air quality, and surface sampling for chemical residue. All testing protocols, acceptance criteria, and trend analysis should be documented to demonstrate continuous improvement

Legal Protection Through Proper Records

Detailed documentation is important for legal defence purposes rather than for regulatory compliance. Incident response records document the appropriate response to cleaning-related accidents, such as spill control, exposure procedures, and clean-up activities. Such records demonstrate a duty of care and may be crucial when liability is claimed.

Objective validation of cleaning program effectiveness is offered by third-party verification by professional inspections or certification programs. Documentation must cover the credentials of the inspectors, evaluation procedures and plans of correction in case of any shortcomings.

Digital documentation systems are becoming the standard of compliance records and have the benefit of ease of access, searchability, and secure storage. Such systems must incorporate proper security measures, routine backup, and retention policies which are in accordance with the regulatory guidelines.

Conclusion

Cleanliness as a form of workplace safety is not only a regulatory requirement of businesses in Florida, but a strategic move in terms of business efficiency, health and wellness of employees, and business reputation.

With the adoption of systematic cleaning procedures that conform to the federal OSHA requirements, as well as those that are unique to the state of Florida, businesses establish safe conditions that safeguard their employees and their financial interests.

The most effective compliance initiatives incorporate cleaning procedures as part of the larger safety programs, and they understand that sanitation is a pillar of hazard prevention in the workplace.

By using appropriate documentation, employee training and implementation, Florida companies can turn cleaning, what is traditionally a janitorial role, into a strategic risk management process.

With the ever-changing regulatory requirements, flexibility and awareness of the changing standards will be necessary. Companies that implement effective cleaning procedures at this stage will be in a better position to adjust to new demands in the future and will not lose their operational continuity and compliance status.

By viewing cleanliness as an investment rather than an expense, Florida businesses can reap significant benefits in terms of reduced absenteeism, increased productivity, a longer lifespan for facilities and equipment, and improved regulatory status. This transforms workplace safety due to cleanliness from a regulatory cost into a business opportunity.